measuring dry film thickness|nominal dry film thickness : distributors Accurate measurement of dry film thickness is critical, especially in industries, such as automotive, aerospace, and construction. Users can follow the best practices listed below for using electronic DFT gauges correctly. webrun - Que tal correr ao lado do personagem mais veloz. - Facebook . . run ·

{plog:ftitle_list}

Use este Gerador de personagens aleatórios da Disney para encontrar incontáveis nomes de personagens da Disney aleatórios para sua próxima aventura de jogo, história ou .

Accurate measurement of dry film thickness is critical, especially in industries, such as automotive, aerospace, and construction. Users can follow the best practices listed below for using electronic DFT gauges correctly.A dry film thickness (DFT) gauge, often referred to as a coating thickness gauge, can be used to measure the thickness of any of these coatings when dry. Measuring dry film thickness .

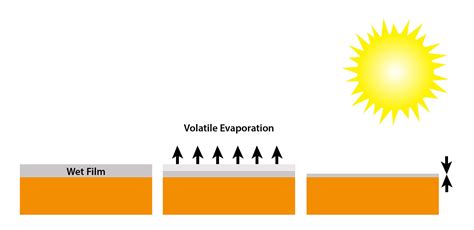

The components are often written as a ratio or as a percentage and can be used to predict the dry film thickness (DFT) when the wet film thickness (WFT) is known. The predicted DFT can be calculated from the WFT using the following formula: . we have a range of electronic gauges that measure dry film thickness on any ferrous and non ferrous .Dry film thickness instruments that measure over steel operate on a magnetic principle. So it stands to reason that gage accuracy might be adversely affected by variations in the steel’s inherent magnetic properties. One of those .What is dry film thickness (DFT)? Dry film thickness (DFT) is the thickness of a coating as measured above the substrate. This can consist of a single layer or multiple layers. DFT measures the total (not the individual layers). DFT is measured on cured powder coatings at ambient temperature. Why measure dry film thickness?The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . DeFelsko manufactures hand-held, non-destructive coating thickness gages ideal for measuring the dry film thickness on Printed Circuit Boards (PCBs .

Wet-film thickness gauges help determine how much material to apply wet to achieve a specified dry-film thickness provided that the percent of solids by volume is known. They measure all types of wet organic coatings, such as paint, varnish, and lacquer on flat or curved smooth surfaces.

One of the most recognised, destructive methods in the coating industry is to use a paint inspection gauge (also referred to as a Tooke gauge or the PIG). The PIG is a popular method for determining dry film thicknesses on non-metallic substrates.. PIGs are available in various models. Some contain one cutter with an angled cutting edge suitable for a specific thickness .

Film thickness is the measurement result, which is obtained from a coating according to an agreed, standardized, precisely described and carefully applied measuring method (Fig. 1). The DIN EN ISO 2808 [1] describes several methods for determining wet film thickness, dry film thickness, and the thickness of unbaked powder coatings.Dry-film thickness can be measured either in a destructive or non-destructive manner. “Non-destructive paint thickness gauges generally fall into one of three categories,” reports David Beamish, general manager of DeFelsko Corp. in Ogdensburg, N.Y. Use “magnetic gauges for measuring over steel, eddy current gauges for measuring over most .3.1.8 dry film thickness, n—the thickness of a coating (or coating layers) as measured from the surface of the substrate. 3.1.8.1 Discussion— If the surface of the substrate is roughened, the dry film thickness is considered the thickness of the coating or coating layers above the peaks of the surface profile. 3.1.9 ferrous, n .

1.1 This practice describes the measurement of dry film thickness of coating films by microscopic observation of precision angular cuts in the coating film. Use of these procedures may require repair of the coating film. This practice is intended to supplement the manufacturers' instructions for the manual operation of the gages and is not intended to replace them.Ultrasonic coating thickness measurement is now an accepted and reliable testing routine used in wood industries. The standard test method is described in ASTM D6132. “Standard Test Method for Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using an Ultrasonic Gage” (2022, ASTM).

The measurement of film thickness holds significance for various manufacturing and research facilities. Fluctuations in the thickness of paint or coating can impact multiple properties crucial to the end product, including color, gloss, hardness, adhesion, and .

1.1 This test method covers the measurement of dry film thickness (DFT) of coating films by microscopic observation of a precision-cut, shallow-angle crater bored into the coating film. This crater reveals cross sectional layers appearing as rings, whose width is proportional to the depth of the coating layer(s) and allows for direct .ASTM D1005, Standard Test Method for Measurement of Dry Film Thickness of Organic Coatings Using Micrometers [26] ASTM D1212, Standard Test Methods for Measurement of Wet Film Thickness of Organic Coatings [27] ASTM D4414, Standard Practice for Measurement of Wet-film thickness by Notch Gages [28]

1.1 This test method describes the use of ultrasonic film thickness gages to measure accurately and nondestructively the dry film thickness of organic coatings applied over a substrate of dissimilar material. Measurements may be made on field structures, on commercially manufactured products, or on laboratory test specimens. These types of gages .Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals1 This standard is issued under the fixed designation D7091; the number immediately following the designation indicates the year of

Measuring WFT is important to predict the final Dry Film Thickness (DFT) and to ensure that the paint is applied according to the manufacturer's recommendations. Techniques for measuring WFT include the use of notched gauges, which are dragged across the wet coat to leave a track that can be measured for thickness.The new Elcometer 456 coating thickness gauge sets new standards measuring the thickness of a coating, helping you to become more efficient. Integral coating thickness gauges are ideal for single handed operation as the wide footprint of the Bigfoot™ internal probe provides greater stability during dry film thickness measurment - allowing for consistent, repeatable and .

nominal dry film thickness

1.1 This test method covers the measurement of film thickness of dried films of paint, varnish, lacquer, and related products using micrometers. Procedures A and B utilize stationary micrometers and Procedures C and D, hand-held micrometers. Procedures A and C are not recommended for films less than 12.5 μm (0.5 mils) in thickness. Appendix 7: Method for Measuring Dry Film Thickness on Coated Steel Pipe Exterior. Appendix 7 was added to accommodate pipe coaters that need to determine coating thickness conformance on non-flat (or non-plate) areas, including smaller pipe sections on a cart or rack and longer pipe spools. Figure 15 Figure 15 The issues that determine what method is best for a given coating measurement include the type of coating, the substrate material, the thickness range of the coating, the size and shape of the part and the cost of the equipment. Commonly used measuring techniques for cured organic films include nondestructive dry film methods such as magnetic, eddy current, . How to Measure Dry Film Coating Thickness . A standard dry film thickness test involves using a hand-held or a remote-operated dry film thickness measurement gauge to analyze the surface. Depending on the substance material and coating type, you may go for either a magnetic induction, electromagnetic, eddy current, or ultrasonic dry film .

Pre-calibrated with 4 surface profiles, is designed to measure dry film thickness on shot or grit blasted substrates. Elcometer 456 IPC Industrial Protective Coating Thickness Gauge; Simple, fast & accurate coating thickness measurements for the industrial paint & powder market. Elcometer 415 Paint & Powder Coating Thickness GaugeDry film thickness (DFT) or coating thickness is arguably the most important measurement made during the application and inspection of protective coatings. Coatings are designed to perform their intended function when applied within the DFT range as specified by the manufacturer. Correct paint thickness ensures optimum product performance.measure the thickness of a dry film of a nonmagnetic coating applied on a magnetic substrate using commercially available magnetic gages. These procedures are intended to supplement manufacturers’ instructions for the manual operation of the gages and are not intended to replace them. 1.2 The procedures for calibration and measurement are“How can I measure my coating dry film thickness?” It is important to apply coatings within the coating manufacturers recommended Dry Film Thickness (DFT). Too little DFT and the coating may fall short of providing the proper protection, whereas too much DFT may cause mud cracking in the film, or unnecessary use of cos

DeFelsko’s PosiTector 200 coating thickness gage is ideal for non-destructively measuring the dry film thickness of coatings on concrete and masonry substrates. . (Standard or Advanced) is ideal for measuring most paint and coatings on concrete applications. With a paint thickness measurement range of 50 to 3,800 µm (2 to 150 mils), this .

ремонт влагомера wile 55

сколько стоит влагомер зерна

WEBO Linda 777 Slots oferece aos jogadores a experiência de usuário da mais alta qualidade. O design da interface do jogo é meticuloso, permitindo que os jogadores sintam a alta qualidade e sofisticação do jogo. Com belos efeitos sonoros, ele pode não apenas aumentar a tensão e a emoção do jogo, mas também proporcionar aos jogadores uma .

measuring dry film thickness|nominal dry film thickness